Shanghai Zhengfu Food Processing Machinery Engineering Co., Ltd. was established in 2019 as a joint venture between Shanghai Zhengcheng Mechanical and Electrical Manufacturing Co., Ltd. and FUKUDA Co., Ltd., located in Songjiang District, Shanghai Zhengfu is an enterprise specializing in the research, development, production, aggregate, industry, and trade of food machinery. With the continuous exploration, research, and application of advanced technology, the company's development has begun to take shape and has advanced production equipment, rich manufacturing experience, high quality scientific research personnel, and a professional after sales service team.

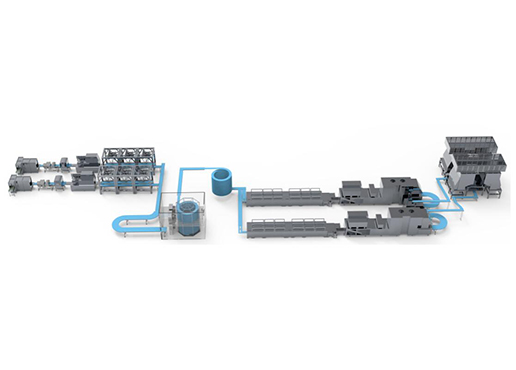

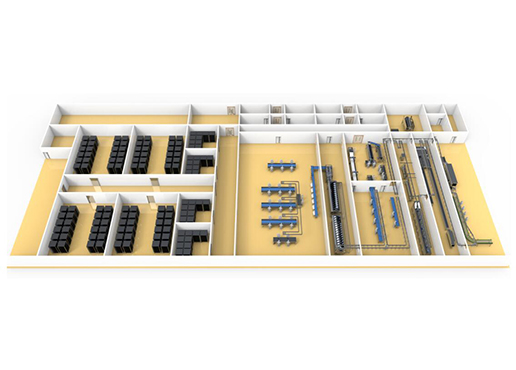

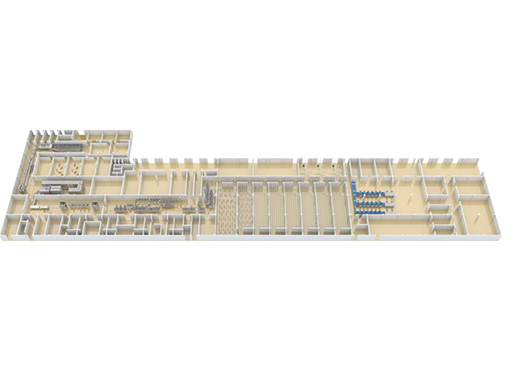

The company's products have been widely used in various fields, all over the country, and exported to overseas countries and regions. We have built a Chinese cuisine production line with an annual output of 4,300 tons, a bone soup production line with an annual output of 5,500 tons, a deep-frying and baking line with an annual output of 4,300 tons, a siu mai production line with an annual output of 1,300 tons, a baozi production line with an annual output of 1,400 tons, and a wonton production line with an annual output of 2,100 tons.We always uphold high quality products, preferential prices, and good after sales service to win the trust of every customer.

021-57780264

021-57780264