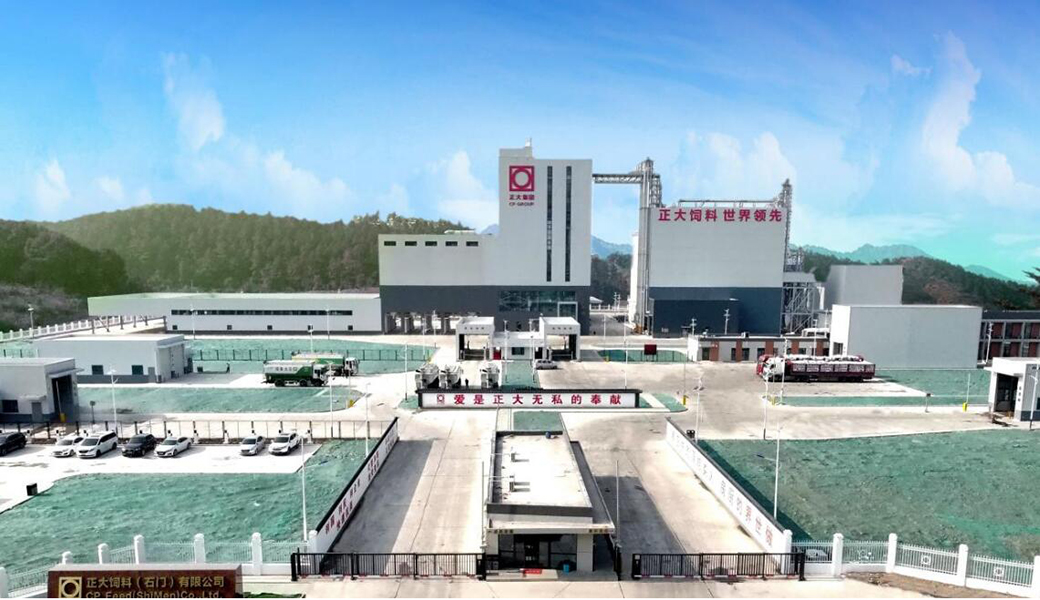

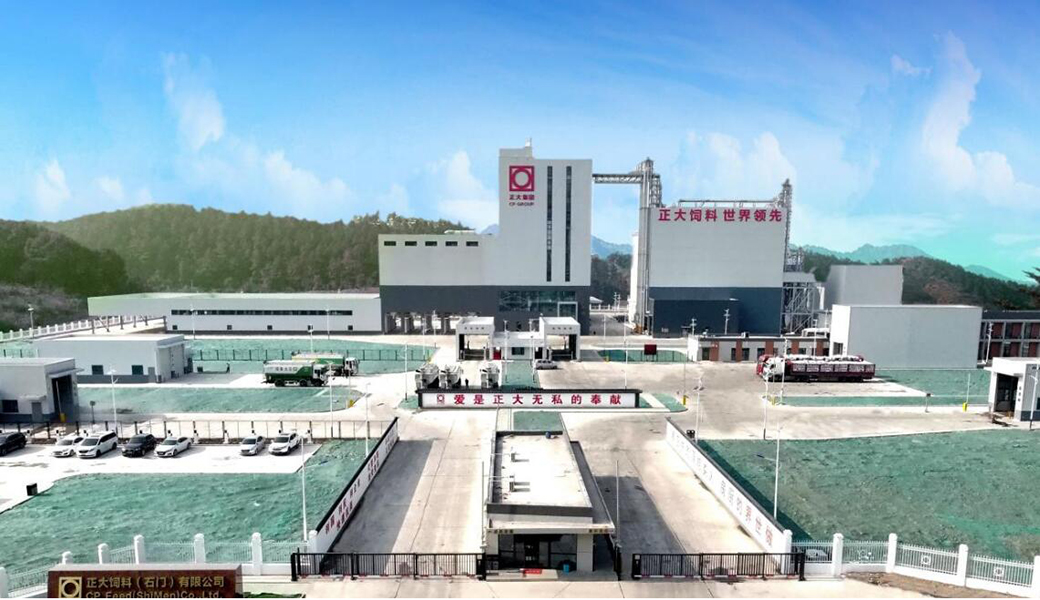

CP (Shimen) Annual Production of 400000 Tons of Feed Factory Formally Completed and Put into Production

At the beginning of the new year, there are many good news. Recently, the opening ceremony of the feed factory of Zhengda Feed (Shimen) Co., Ltd. was held grandly. Zhengda Electromechanical Enterprise - Shanghai Zhengcheng Electromechanical Manufacturing Co., Ltd., as the EPC general contractor of the project, was invited to participate in the celebration.

Zhengda Feed (Shimen) Co., Ltd. Feed Factory, as a typical demonstration industrial chain project of Zhengda Group to build and serve northern Hunan, is located in the High tech Industrial Development Zone of Shimen County, Hunan Province. It covers an area of 100 acres, with a total investment of about 230 million yuan and an annual output of 400000 tons of high-end pig feed.

With strong support from local governments at all levels, group headquarters, and local sister units, Shanghai Zhengcheng adheres to the principles of high standards, strict requirements, and scientific management, overcomes numerous difficulties, and works together with Shimen Zhengda to successfully complete the overall content of civil engineering, steel structure, and equipment in less than 240 days. The factory has been put into operation smoothly.

Produced by Zhengda, it must be a high-quality product. Shimen Factory has multiple leading technologies in the domestic and international industries.

01 Precise epidemic prevention, safe and reassuring

The entire factory area is divided into raw material and finished product zones, office and living zones, personnel and material zones, equipped with modern fully automatic washing and disinfection facilities. From entering the factory to leaving the factory, the entire process of safety and epidemic prevention is controlled without blind spots, allowing customers to rest assured and satisfied.

02 One card connection, easy and efficient

The project plan is for a top tier intelligent one card system in China, with one card in hand for worry free operation throughout the entire process, from entering the factory, weighing, loading and unloading, weighing, and leaving the factory, saving manpower and efficiency, greatly improving the experience of all partners.

03 Grinding without warehouse, pioneering technology

Adopting the group's self-developed non crushing production process, simplifying the process, reducing noise, making workers more convenient and healthy in production, while reducing civil engineering and equipment investment by more than 3 million yuan, making innovation more valuable.

04 Micro self matching, easy and effortless

Adopting a first-class fully automatic trace element batching system in China, automatic batching, pre mixing, and cleaning are carried out to meet the needs of multiple batches in one feeding. A liquid mixer is equipped to mix dry and wet materials simultaneously, shortening the mixing time and improving the batching production capacity.

05 screen replacement without stopping, production capacity is still very high

Adopting non-stop automatic screen changing crusher, this crusher is independently developed and produced by Shanghai Zhengyi drawing on advanced technology from Europe and America, combined with more than 40 years of production experience of Zhengda Group. Each screen changing can save 15-25 minutes of time, greatly reducing no-load power consumption. At the same time, the production capacity reaches 30-45 tons/hour, 10-20% higher than industry products, reducing costs and increasing efficiency.

06 CPS-PLUS, Experience Intelligence

Adopting the CP Smart system, a feed mill intelligent control system independently developed by Shanghai Zhengcheng, combined with practical application scenarios, data is automatically collected, analyzed, and instructions are issued for continuous upgrading. It can achieve fully automatic pull production, with traceable processes and precise management in all aspects, making production lighter and easier.

07 One click Start, Enjoy Leading Experience

Using Shanghai Zhengcheng's unique data algorithm and customized program development, the machine enters normal full load granulation state within 4 minutes of startup. Each startup increases the effective granulation time by 5-10 minutes, and on-site startup does not require personnel, making the central controller and pelletizer a different position to experience granulation.

08 IoT, the eyes of the factory

Adopting the IoT system independently developed by Shanghai Zhengxin, the factory's automatic infrastructure configuration is comprehensively upgraded, changing the working state of workers around the factory, allowing the factory to operate around workers, sitting in the control center, and everything is under control.

Source production, feedback production, Shanghai Zhengcheng always keeps in mind its mission, combines advanced technology at home and abroad with years of production and engineering experience of Zhengda Group, to build a convenient, efficient, safe and environmentally friendly high cost-effective feed factory engineering service that meets the factory's positioning and customer needs, and assists customers.

021-57780264

021-57780264