Digital factory:

Built according to the high cleanliness standards of food processing plants, creating a 100000 level purification workshop. The digital central control room can monitor various aspects of the packaging factory in real time, collect production data, equipment data, and warehouse data in real time. Key process automation, digital monitoring of the entire factory, and traceability of the entire process.

Imported equipment:

We have introduced the German Kaifu KMD78 multi station integrated machine and the Japanese Asano FLC+PLS positive and negative pressure automatic high-speed machine. The equipment investment is large, the production efficiency is high, the product quality is guaranteed, and it helps to produce high-quality food trays.

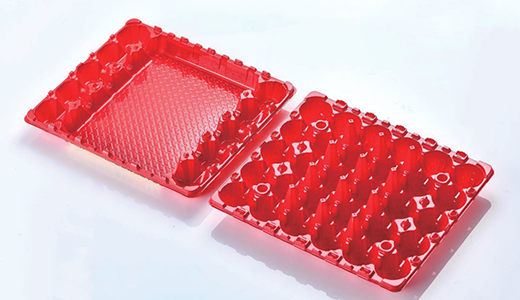

Comprehensive product types:

We can produce trays made of various materials such as PP/PET/PS/EVOH, providing safe and healthy packaging for frozen food, refrigerated food, and ambient temperature food.

Genuine materials:

Select non-toxic, odorless, and low-density environmentally friendly materials, strictly control the raw material ratio, and ensure that the product has good barrier properties, safety, and stability. The product is moisture-proof, anti-seepage, high temperature resistant, and low temperature resistant. Even in extreme temperatures of minus 45 ℃ and above 139 ℃, it can maintain safety and stability without producing harmful substances.

AI scheduling:

It can be integrated with the production plan and packaging ware�house data of client food factories, helping food factories achieve packaging inventory optimization and intelligent scheduling of packaging factory production plans.

021-57780264

021-57780264