As a poultry farming engineering system service provider, we focus on our full chain service capabilities and build sustainable farming solutions through five dimensions:

EPC full chain delivery:

covering large-scale breeding projects such as laying hens, broiler chickens, and breeder chickens, providing full cycle services from planning and design, civil construction to equipment integration (including automated feeding and manure treatment systems), and a standardized delivery system to ensure efficient project implementation.

Localization technology adaptation:

Integrating European and American design concepts with local environmental characteristics, a team of senior environmental control engineers customizes differentiated ventilation solutions, which have been verified through multi-climate zone projects to effectively balance environmental stability and energy consumption control.

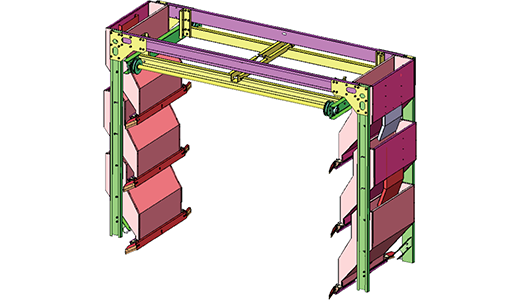

Independent intelligent manufacturing system:

The Yangtze River delta production base is equipped with intelligent production lines, and core equipment is independently developed and produced. Through full process quality control and modular design, the stability of equipment operation and maintenance convenience are ensured.

Century long experience accumulation:

Inheriting the breeding management experience of CP Group, the engineering team deeply embedded pain point designs for equipment usage scenarios, synchronously provided expert support systems for breeding technology, environmental control and ventilation, and built a risk prevention and control loop.

Smart farming transformation:

Independently develop IoT environmental intelligent control systems, chicken flock inspection robots and other digital products to achieve intelligent linkage of key links such as environmental monitoring and production warning, and help customers

021-57780264

021-57780264