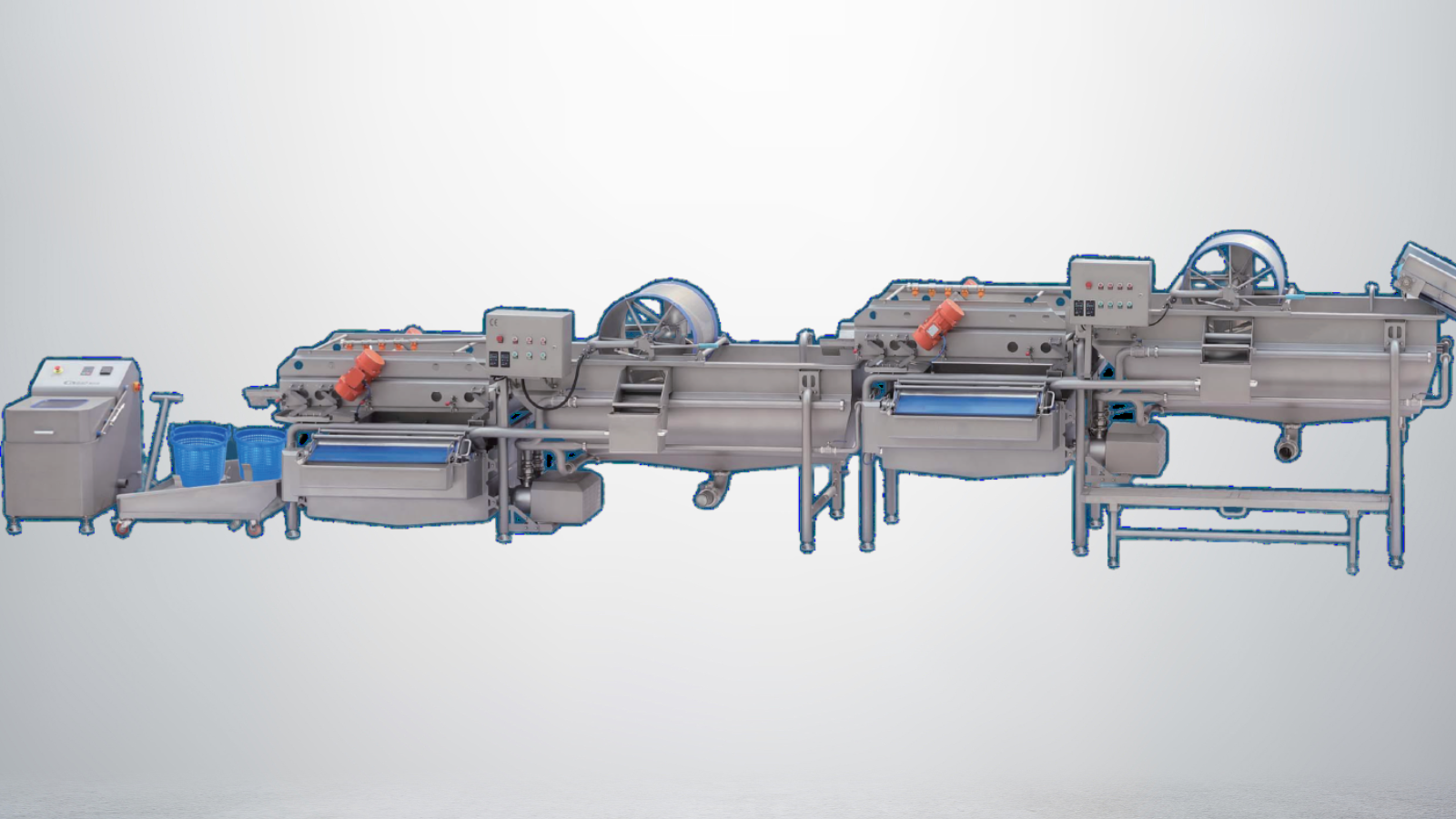

Function overiew:

The horizontal mixing and rotating water fow is used for cleaning, and the impuri-ty removal device automatically separates the bud and the bud shell. After separa-tion, the bean sprouts are expored with the water fow, and then transpored to the next process after being drained through the vibrating screen hole to separate the sprout shells.

Technical analysis:

◎ Rotating mixed water fow cleaning, extend the cleaning path of the same box, and improve the cleaning efect;

◎ Automatic impurity removal device, frequency conversion control, slot fxation, automatic separation of impurities in bud and bud shell, without manual interention;

◎ Conical bottom design of sediment sedimentation tank, perorated screen fltration, centralized storage and discharge of sediment, 360 ° rotation of sewage valve, suitable for applications designed in diferent workshops;

◎ The circulating water tank is equipped with a cage impurity removal device, which can automatically remove impurities. After the water fow is fltered, the water for the tank body is recharged through the circulating pipeline, and the pipeline is controlled by a manual valve;

◎ Clean the ozone generator for the frst time to decompose pesticide residues and efectively kill bacteria;

◎ The secondar cleaning of the ice water unit can reduce the material temperature, improve the material quality, and extend the fresh-keeping period;

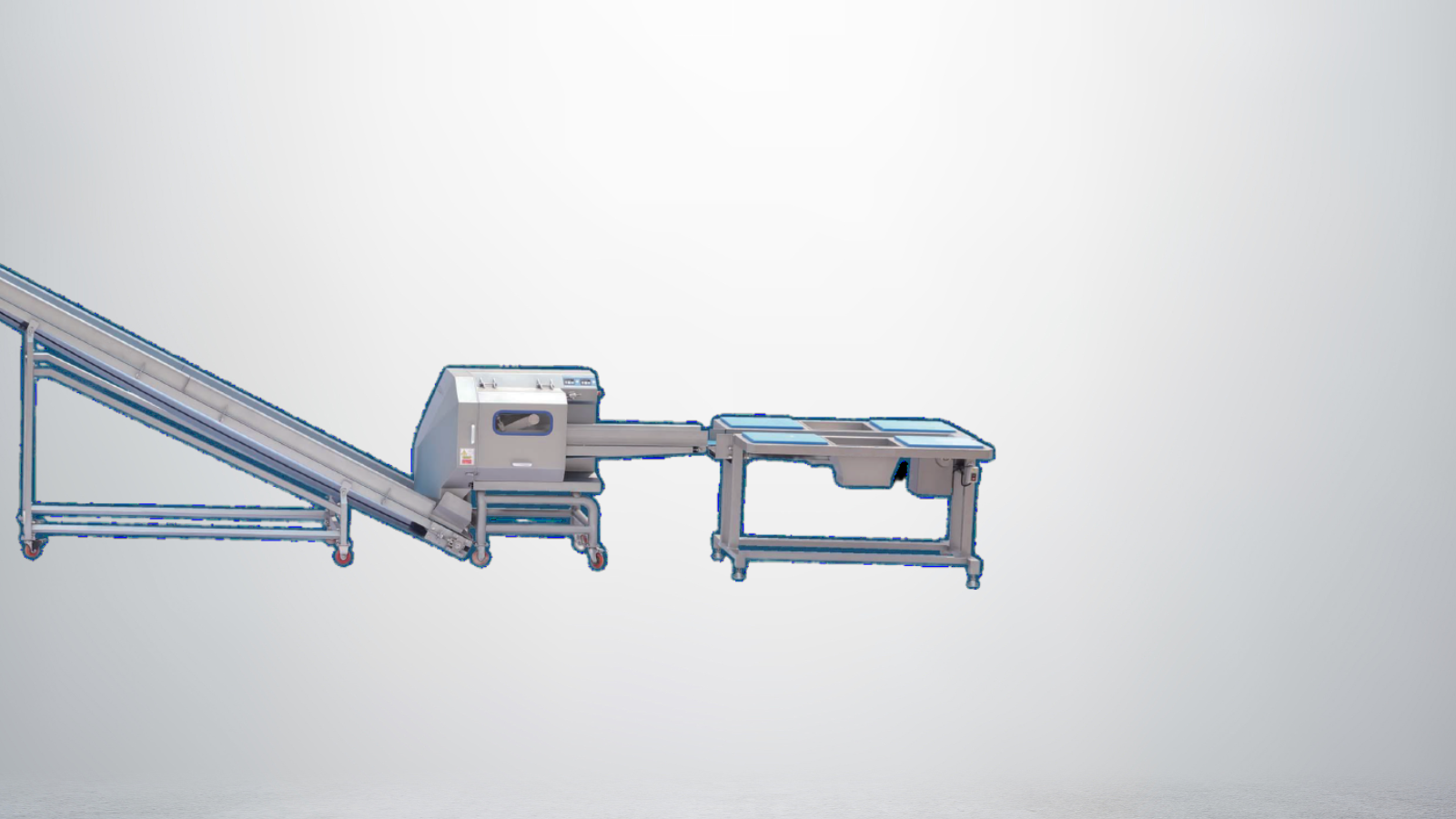

◎ Drip and transpor with perorated plate to separate water on the surace of sprouts.

021-57780264

021-57780264