In the golden autumn of October, good news spreads frequently. Recently, the Indonesian feed mill project upgraded and renovated by the overseas Southeast Asian team of Zhengda Electromechanical Enterprise and the Electric Control R&D Center of Shanghai Zhengcheng Electromechanical Manufacturing Co., Ltd. has successfully passed the acceptance inspection. Zhengda Electromechanical Enterprise has once again gained recognition and favor from international customers with its rich experience in transformation and upgrading, high-quality and stable software and hardware products, agile customized development response speed, and hardworking and efficient team services.

As a well-known enterprise in Indonesia and even the entire Southeast Asian region, our client company has long maintained a leading position in the feed industry. However, with the rapid advancement of production technology and the increasing market demand, its original production lines are facing challenges of low production efficiency and high energy consumption due to aging equipment and outdated production line designs, which are no longer able to meet current and future market demands.

In this context, the overseas Southeast Asian team of Zhengda Electromechanical Enterprise, in collaboration with the Shanghai Zhengcheng Electric Control R&D Center, has jointly launched this three-month digital upgrade and renovation project. It is reported that the feed mill that needs to be renovated this time has a total of 5 production lines, including 2 aquatic granulation lines, 2 livestock and poultry granulation lines, and 1 aquatic puffing line. To complete the upgrade and transformation of the entire factory control system under the continuous production pressure of customers undoubtedly poses a great challenge to the team.

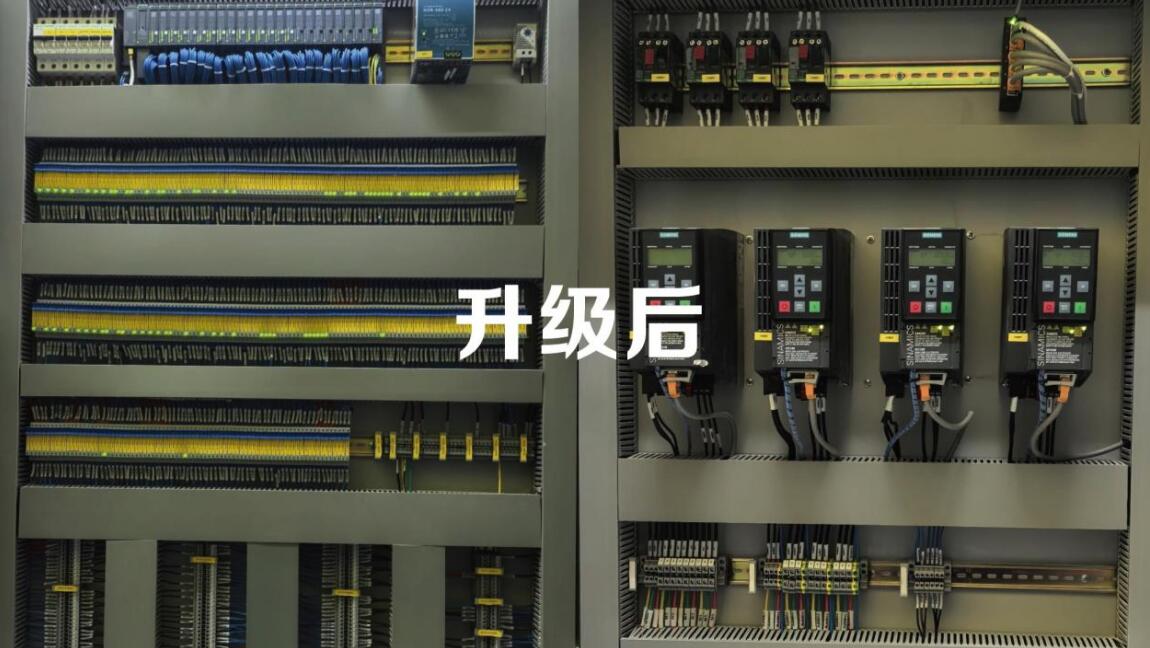

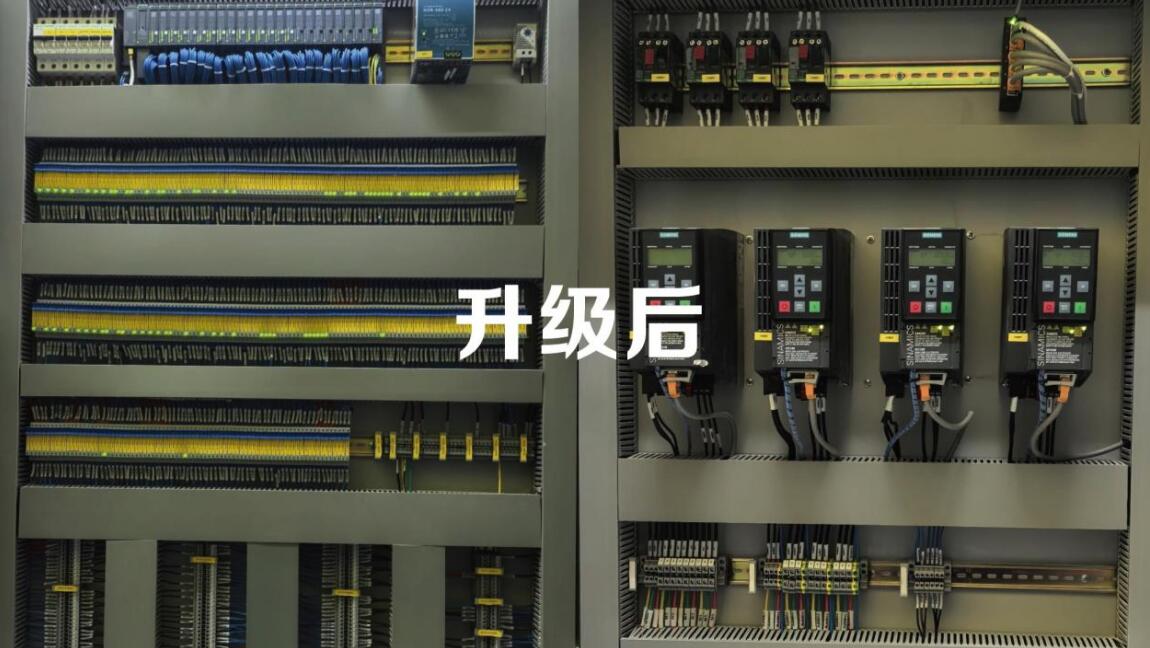

After summarizing past project experience and conducting multiple rounds of in-depth on-site research and technical discussions, the Shanghai Zhengcheng team accurately identified the needs and challenges of customers, and proposed a comprehensive digital upgrade plan to address issues such as equipment aging, low production efficiency, and high energy consumption. Starting from five key points of automation, equipment protection, capacity improvement, energy management, and data interconnection, the feed mill underwent a comprehensive and in-depth transformation.

① Automation Innovation: Prior to the renovation, equipment was mostly imported from Europe, Taiwan, and other regions, which resulted in issues such as inadequate control chain, poor operational friendliness, and low automation programs. Shanghai Zhengcheng has introduced the latest Internet of Things (IoT) technology in its renovation, combined with its independently developed CPS intelligent control system, to achieve automated control of the entire factory production process, significantly improving the convenience of equipment operation and production efficiency.

② Equipment protection enhancement: By adding high-precision sensors and intelligent algorithms, the operating status of equipment can be effectively monitored, potential faults can be warned in advance, the equipment failure rate can be significantly reduced, and the overall equipment efficiency (OEE) can be improved, saving customers a lot of operation and maintenance costs.

③ Capacity leap: Relying on the CPS system's pull based production mode and optimized production line rhythm algorithm, the production capacity has achieved a significant increase of 30% -50%, providing strong support for the customer group's market expansion.

④ Energy consumption optimization: In addition to increasing production capacity, the CPS system also performs outstandingly in energy management. Through precise regulation of energy, it achieves real-time monitoring of no-load and low load and optimizes production rhythm, effectively reducing energy consumption by 10% -20% and helping enterprises achieve green production goals.

⑤ Data fusion: Before the transformation, the systems operated independently and had isolated information, which not only resulted in low production efficiency but also posed great challenges to product quality. The Shanghai Zhengcheng team uses IoT technology to break down information silos, achieve data interconnection between various systems within the factory, and seamlessly integrate with customer formula, market, finance and other systems, providing comprehensive, accurate and continuous data support to help enterprises achieve refined management.

It is worth mentioning that the CP Smart system used in the project was independently innovated and developed by Shanghai Zhengcheng Electric Control R&D Center, and has been maturely applied in domestic livestock and poultry factories, aquaculture factories, ruminant factories, and premix factories. CPS system is an intelligent control system of feed factory with independent intellectual property rights, and has obtained the software copyright certificate issued by the China National Intellectual Property Administration. The system includes CPS system basic functions, intelligent logistics one card system, granulator automatic control system, pull production system, equipment intelligent operation and maintenance system, energy management system, and IoT platform system, covering a complete set of software systems for the operation, logistics, warehousing, quality control, and production of the feed mill, providing intelligent and convenient services for the feed mill.

During three months of intense construction and commissioning, the overseas Southeast Asian team of Zhengda Electromechanical Enterprise and the Shanghai Zhengcheng Electric Control R&D Center team accurately grasped customer needs, demonstrated excellent technical strength and efficient execution, completed all construction and renovation in an astonishing time, and successfully completed acceptance in October. The upgraded feed mill has achieved a significant increase in production efficiency, a significant reduction in energy consumption, stricter quality control, and a new level of management informatization, bringing advanced production technology and significant economic benefits to the customer group.

In recent years, with the steady promotion of the "going global" strategy, Zhengda Electromechanical Enterprise has actively responded to the wave of globalization and successfully established roots in Southeast Asian countries such as Thailand, Indonesia, Malaysia, as well as multiple regions including Japan and South Korea, achieving extensive business layout and vigorous development. The successful implementation of a number of international projects such as the Indonesian feed mill has not only established a good brand image for Zhengda Electromechanical Enterprise in overseas markets, but also significantly increased the company's market share, further consolidating the company's leading position and strong strength in automation and digital solutions in feed mills, breeding farms, food factories and other fields. As a technological pioneer in the industry, Zhengda Electromechanical Enterprise will uphold innovative concepts, deepen technological research and development, continuously explore markets, provide more personalized, high-quality, efficient, and intelligent solutions for partners worldwide, work together to promote the transformation, upgrading, and prosperous development of the entire industry.

021-57780264

021-57780264